Hydrogen Production by

Rhodobacter Sphaeroides O.U.001

Introduction (TOP)

Hydrogen is a clean and efficient fuel, and a potential

substitute for fossil fuels in the long run.

Biological hydrogen production is environmentally friendly, uses

renewable resources and does not require complex equipment

Currently low production rates and high substrate costs limit the

economical feasibility of biological hydrogen production. Increasing

feasibility requires detailed research.

Objectives (TOP)

Studies made by our group aim the following:

Development of an understanding of the hydrogen production

characteristics of the bacteria

Increasing the hydrogen production rates through optimization of

variables

Investigation of the possibilities of decreasing the cost

Scaling-up of the photobioreactor for the biological hydrogen

production.

Microorganisms Producing

H2 (TOP)

Algae (Oxygenic photosynthesis)

H2O

à H2

+

½ O2

Cyanobacteria (Oxygenic photosynthesis)

H2O

à H2

+

½ O2

Anaerobic bacteria (Fermentation)

C6H12O6

à H2+

CO2+

organic

acids

Photosynthetic bacteria (Anoxygenic

photosynthesis)

organic

acids

+

H2O

à H2

+

CO2

Studies

of the M.E.T.U. Biohydrogen group with R.sphaeroides OU 001(TOP)

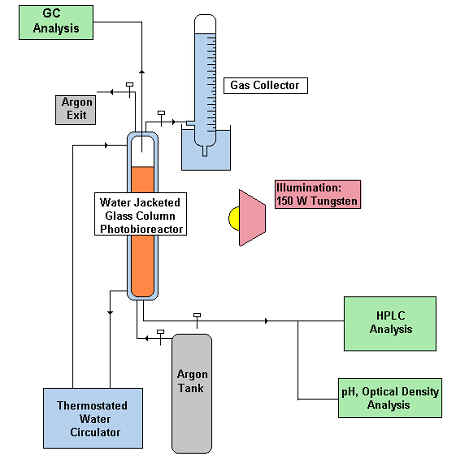

Hydrogen

Production Setup (TOP)

Typical Conditions

(TOP)

The photosynthetic bacteria evolve hydrogen from

organic carbon compounds when subjected to illumination under an

inert anaerobic atmosphere. Below are typical conditions used in

hydrogen production experiments.

Temperature: 30-35 °C

Initial pH: 6.8-7.0

Nutrient medium: (Modified from Biebl and Pfennig,

1981)

Malate / Wastewater (Carbon) Glutamate (Nitrogen)

Salts+Vitamins

Light Intensity: (Tungsten)150-250 W/m2

Atmosphere: Pure argon

Volume: 400 ml

Selection of

microorganism (TOP)

Each group of microorganism has its advantages and

drawbacks for hydrogen production. The following advantages of

Photosynthetic Bacteria make them particularly suitable for

biological hydrogen production.

High substrate conversion efficiency.

Ability to utilise a wide wavelength range of

sunlight.

Ability to utilise a large variety of compounds

for growth or H2 production.

Ability to survive under changing conditions. Among

the photosyntetic bacteria, R. sphaeroides was observed to have a

high hydrogen production rate. Therefore this bacterium was selected

and studied for hydrogen production.

Factors

Affecting Hydrogen Production (TOP)

Effect of temperature and light intensity

There are many factors which influence hydrogen (Arik et.

al.,1996) production by R. sphaeroides in one way or the other.

First, the effect of parameters that could be easily manipulated and

set constant- such as temperature, light intensity- were

investigated.

Table 1. Influence of

temperature and light intensity

Effect of Substrate Concentrations

Then the effect of substrate concentrations was

examined (Eroğlu et. al.,1999). It was found that high

concentrations of glutamate promoted growth at the expense of

hydrogen production. The effect of glutamate concentration is seen

in Figure 2.

Figure 2 Hydrogen

produced with 15 mM malate and 3 different glutamate concentrations.

Also in this work, kinetic relations between substrate

consumption and hydrogen utilisation were proposed.

Use of Yeast Extract

Use of yeast extract to replace the standard vitamin solution

resulted in an increased rate of hydrogen production (Figure 3)

Moreover, the production started earlier.

Figure 3 Comparison of

hydrogen production with yeast extract (0.2 gl) with that of the

standard vitamin solution

Use of light-dark cycles

Growth and hydrogen production were minimal in the

dark periods but the use of alternating light-dark periods resulted

in an increase in hydrogen produced compared to continuous

illumination.

Figure 4 Comparison of

hydrogen production in photobioreactor exposed to light-dark cycles

(14h-10h) with hydrogen produced in a continuously illuminated

photobioreactor

Continuous

Hydrogen Production (TOP)

By the addition of bacteria and medium with regular

intervals, continuous hydrogen production for long periods, e.g. for

more than two months, was accomplished. Figure 5 shows one of these

runs. (Eroğlu et. al., 1998)

Figure 5 Continuous

hydrogen production by diluting the reactor with 100 ml of fresh

medium and 30 ml bacterial culture every 100 hours.

Use of Wastewater

(TOP)

The cost of the biological hydrogen production can

be decreased by supplying at least a part of the nutrient

requirements for the bacteria by wastewater. Hydrogen production

experiments with the waste water of two common industries-sugar

refinery and dairy plant- were conducted.

Use of dairy plant waste water (Türkarslan et. al., 1998)

:

Waste water on its own did not support bacterial growth. A blend

of waste water with the standard medium resulted in increased growth

and increased hydrogen production compared to the standard medium.

Use of sugar refinery waste water (Yetiş et. al.,

2000):

Hydrogen production was observed in blends of waste water with

the standard medium. Highest hydrogen production rate was obtained

in 20 % waste water. (Figure 6)

Figure 6 Hydrogen

produced by R. sphaeroides using malate only and a blend of malate

and 20 % sugar refinery wastewater.

By-products

(TOP)

Identification and isolation of useful products

other than hydrogen may increase overall feasibility and provide

valuable information on metabolism. Poly-beta-hydroxybutyric acid (PHB),

a biodegradable polymer, is one of the by-products of Rhodobacter

sphaeroides O.U. 001. PHB can be used for production of disposable

bags and containers. Biocompatibility of PHB makes it a desirable

material for medical applications such as controlled drug release

and the production of surgical pins, wound dressing, blood vessel

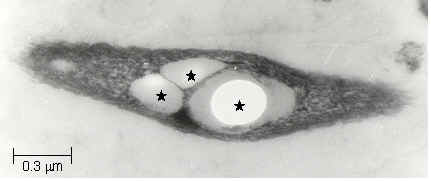

replacements etc.In R. sphaeroides, PHB is accumulated as an

intracellular carbon and energy storage material. PHB is accumulated

as granules localized at different sites of cytoplasm. An electron

micrograph of PHB granules in R. sphaeroides is seen at the left

(Figure 7).

Figure 7. Electron

micrograph of PHB granules (*) in Rhodobacter sphaeroides O.U. 001,

fixed with Glutaraldehyde and Uranyl acetate, dehydrated with

Acetone, stained with Lead citrate.

An example PHB production curve of R. sphaeroides

O.U.001 as a function of time is given in Figure 8. R. sphaeroides

was found to produce more PHB in a blend of sugar refinery waste

water and malate, than from malate alone. This comparison is

displayed in Table 2.

Figure 8. Production of PHB

as a function of time by Rhodobacter sphaeroides O.U. 001 in malate/

glutamate medium

Table 2: Accumulation of PHB

in various media

Metabolism

(TOP)

Information on metabolism is essential to understand

the mechanisms involved in hydrogen production and to identify the

limiting factors. The following information has been obtained from

the literature and from conducted experiments. Hydrogen production

occurs through the operation of a light-dependent, anaerobic TCA

cycle. Electrons produced from the substrate by the TCA cycle are

transferred by electron carriers to the nitrogenase. The nitrogenase

uses these electrons to reduce protons.

Flow of electrons:

Substrate à(TCA

cycle) à

NADàFerredoxinàNitrogenase enzyme

Nitrogenase Reaction: 2H+ + 2e- + 4ATPà H2

R. sphaeroides is capable of several alternative

pathways such as aerobic respiration and phototoautotrophy. Hydrogen

production is practically absent for these pathways. R. sphaeroides

can use a very large variety of carbon and nitrogen sources such as

sugars, organic acids, glycerol etc. for growth. However, substrates

differ greatly in their manner of utilisation, therefore substrates

which promote the hydrogen production pathways are very limited.

Figure 9. Growth curves of R.

sphaeroides O.U.001 with: i)Malate as the carbon source(15 mM) and

glutamate as the nitrogen source(2 mM), ii) Glutamate (2mM) as the

sole carbon and nitrogen source and iii) No carbon source, only

ammonium chloride (2mM) supplied.

Figure 9 illustrates the growth of R. sphaeroides

under various conditions of carbon availability. Malate+glutamate is

the preferred medium. When glutamate is the only carbon and nitrogen

source, cells still grow appreciably. When only ammonium chloride is

present (no carbon source given) the bacteria still grow to some

extent, possibly by utilising their endogeneous reserves, such as

PHB.

Conclusions

(TOP)

High purity (95-99%) hydrogen has been produced in

reactors designed specifically for the purpose.

Variables such as temperature, light intensity and

substrate concentration have been optimized for hydrogen

production.

Kinetic expressions relating substrate consumption

and hydrogen production with substrate concentrations have been

proposed.

Experiments have been conducted in which long term

continuous hydrogen production has been accomplished.

Hydrogen production was found to be possible in

specific blends of wastewater with the standard medium.

The valuable by-product poly-hydroxybutyrate has

been detected and identified.

Future Plans

(TOP)

Improvement of hydrogen production through

optimisation of metabolism. For this purpose investigation and

identification of the genetic structure is also necessary.

Construction and continuous operation of an 8 liter

outdoor photobioreactor.

Investigation of the effect of other parameters,

such as the use of coupled R. sphaeroides-Bacteriorhodopsin systems.

Completion of the characterization and

identification of PHB.

Investigation of the possibility of hydrogen

production from vegetable oil waste.

References

(TOP)

Arık, T., Gündüz, U., Yücel, M., Türker,

L., Sediroğlu, V., Eroğlu, İ., "Photoproduction

of hydrogen by Rhodobacter sphaeroides O.U.001", Proceedings of

the 11th World Hydrogen Energy Conference, Stuttgart, Germany, Vol

3, 2417-2424, 1996

Biebl, H., Pfennig N., "Isolation of Members of

the Family Rhodosprillaceae" M.P. Starr, H. Stolp, H.G. Trüper,

A. Balows, H.G. Schlegel (eds.) The Prokaryotes, Springer-Verlag,

New York, Vol. 1, 267-273, 1981

Eroğlu, İ., Aslan, K., Gündüz,U., Yücel,

M., Türker, L., "Substrate consumption rates for hydrogen

production by Rhodobacter sphaeroides in a column photobioreactor",

J. Biotech., 70: 103-113, 1999

Eroğlu, İ., Aslan, K., Gündüz, U., Yücel,

M., Türker, L., "Continuous hydrogen production by Rhodobacter

sphaeroides O.U.001.", O.R. Zaborsky (ed.) Biohydrogen, Plenum

Press, New York, 143-150, 1998.

Türkarslan, S., Yiğit, DÖ., Aslan, K., Eroğlu,

İ., Gündüz, U., "Photobiological hydrogen production by

Rhodobacter sphaeroides O.U.001 by utilization of waste water from

milk industry.", O.R. Zaborsky (ed.) Biohydrogen, Plenum Press,

New York, 151-156, 1998

Yetiş, M., Gündüz, U., Eroğlu İ., Yücel,

M., Türker, L., "Photoproduction of hydrogen from sugar

refinery wastewater by Rhodobacter sphaeroides O.U.001", Int.

J. Hyd. Eng., 25: 1035-1041, 2000

Yiğit, D.Ö., Gündüz, U., Türker, L., Yücel,

M., Eroğlu, İ. "Identification of by-products in

hydrogen producing bacteria; Rhodobacter sphaeroides O.U.001 grown

in the waste water of a sugar refinery." J. Biotech.

70:125-131, 1999.

[ Home ] [ Members ] [ Researches ] [ Publications ] [ Photos ] [ E-mail ]

|